Engineering, Procurement

and Installation

Ready for our innovations on your next project?

- Fabrication Drawing

- 3D Modelling

- Process Design

- Structural Design

- Compressor After Cooler

- Fuel Gas Conditioning

- Suction Scrubber

- Chemical Injection Skid

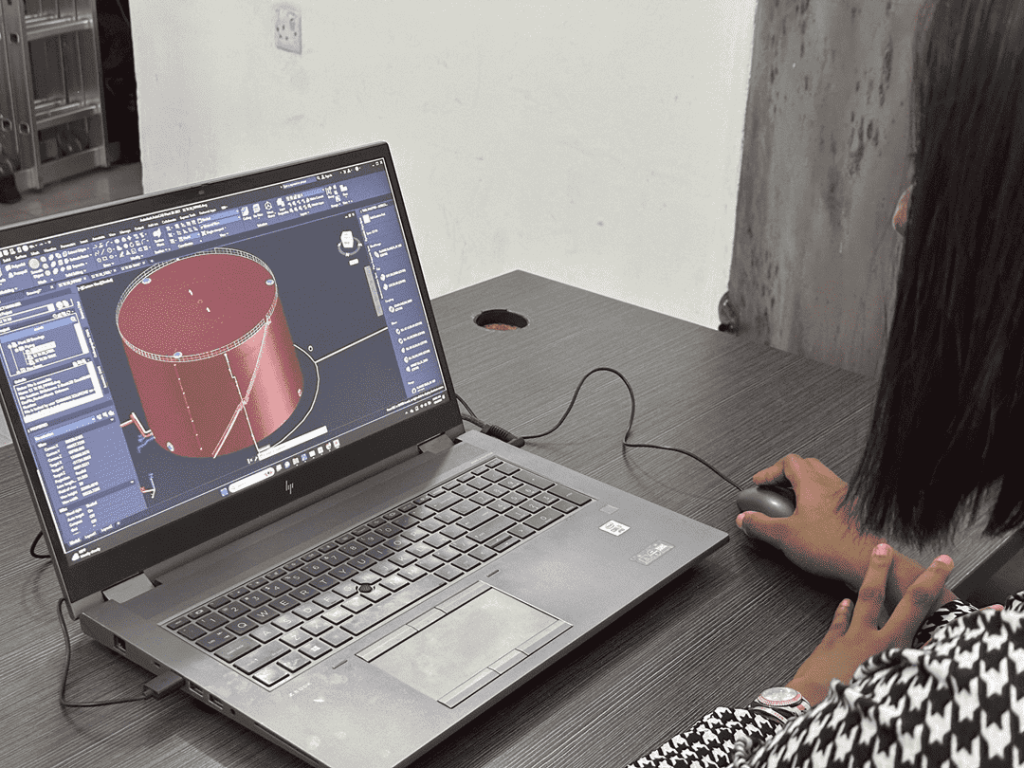

Fabrication Drawing

Precision Engineering for Seamless Manufacturing

We specialize in Fabrication Drawings that bridge the gap between design and production. Our expert drafters and engineers create detailed, high-precision blueprints that serve as a roadmap for manufacturers, ensuring every component is built to specification.

Why Choose Our Fabrication Drawings?

Accuracy & Detailed

We provide comprehensive drawings, including dimensions, material specifications, welding symbols, and tolerance levels.

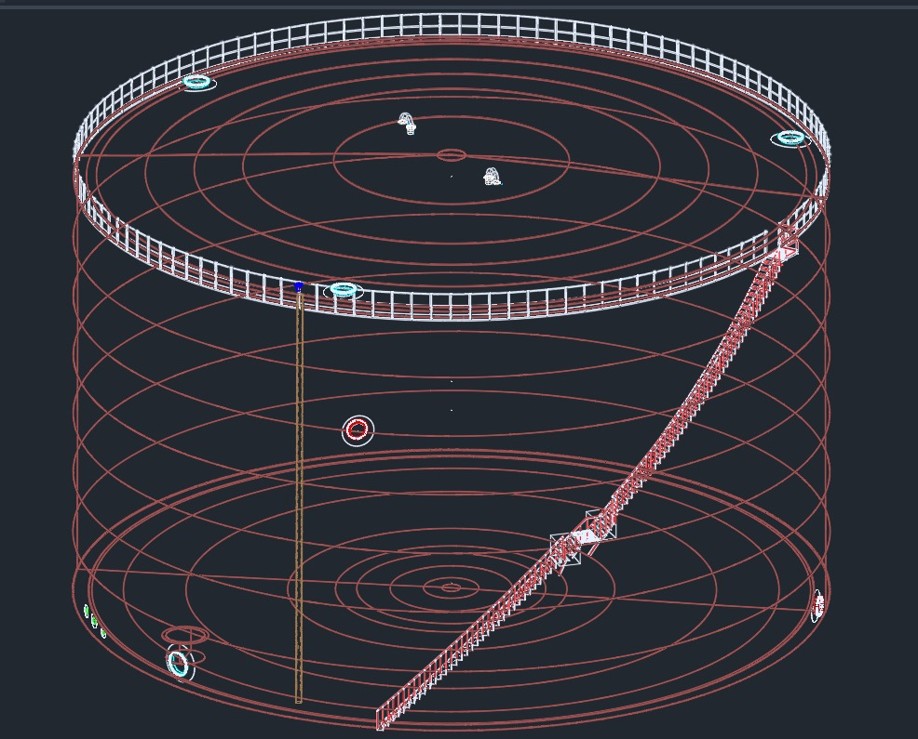

3D & 2D Modeling

Our advanced CAD tools help visualize every part before production.

Compliance & Standards

We adhere to international fabrication and welding standards for quality assurance.

Seamless Collaboration:

We work closely with engineers, architects, and fabricators to ensure precision at every step.

Our Fabrication Drawing Services

- Part & Assembly Drawings – Detailed representations of individual parts and their final assembly.

- Sheet Metal Fabrication Drawings – Cutting, bending, and welding details for sheet metal work.

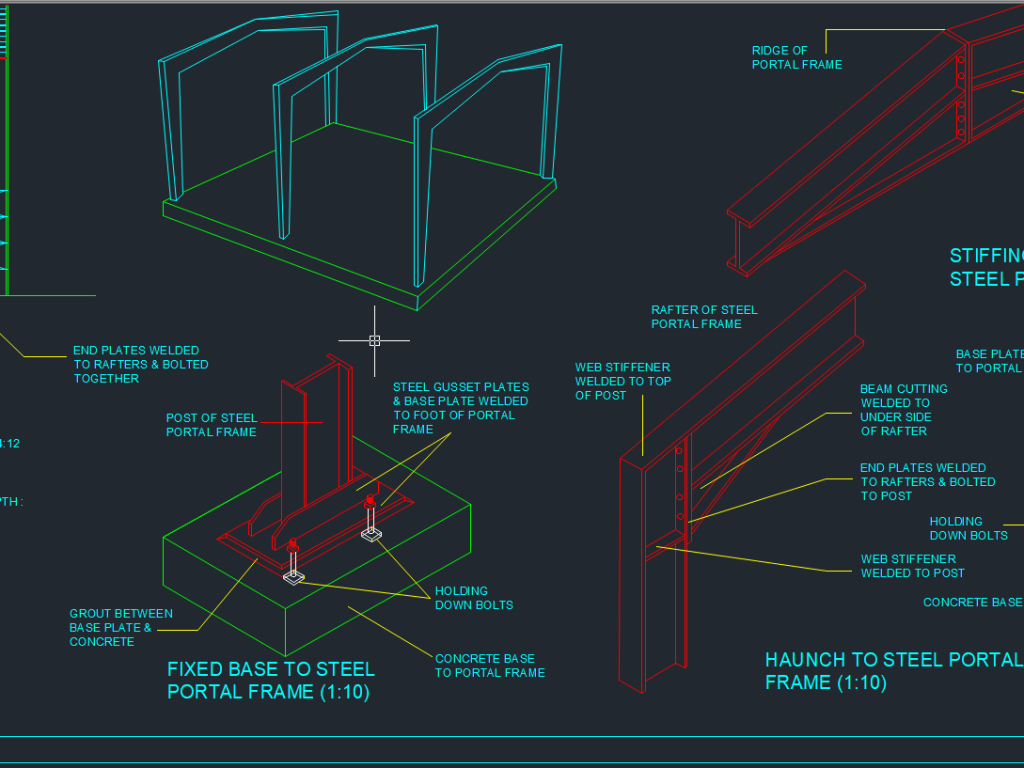

- Structural Fabrication Drawings – Blueprints for beams, columns, and frameworks used in construction and heavy industries.

- Weldment Drawings –Instructions on welding sequences, symbols, and material preparation.

- Bill of Materials (BOM) – A comprehensive list of required materials and components.

Industries We Serve

Construction

Robust designs for structural and architectural projects.

Manufacturing

Precision-driven fabrication for industrial production.

Energy & Power

Structural and mechanical drawings for power plants and grids.

Shipbuilding

Engineered drawings for marine and offshore structures.

Fabricate with Precision – Let’s Talk!

From intricate components to large-scale assemblies, our expert fabrication drawings ensure accuracy, efficiency, and compliance. Contact us today to bring your project to life!

3D Modelling

Precision in Every Dimension.

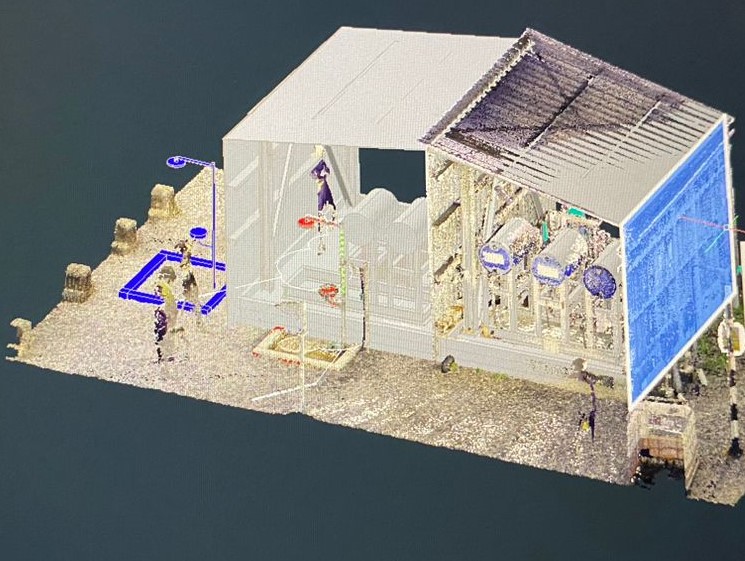

Daramyx Solutions Limited delivers high-quality 3D modeling and rendering for industries worldwide, including architecture, manufacturing, and automotive. Our expert team creates precise models for complex products, enabling motion simulation and design validation. Using advanced software like AutoCAD, Revit, SolidWorks, and Fusion 360, we bring concepts to life with accuracy and efficiency.

Over time, we have developed a well-defined and streamlined process for creating 3D product models. We devote sufficient time and effort to each model to ensure that it meets the desired level of detail, optimization, and impression. Our services are diverse and comprehensive, covering a wide range of areas.

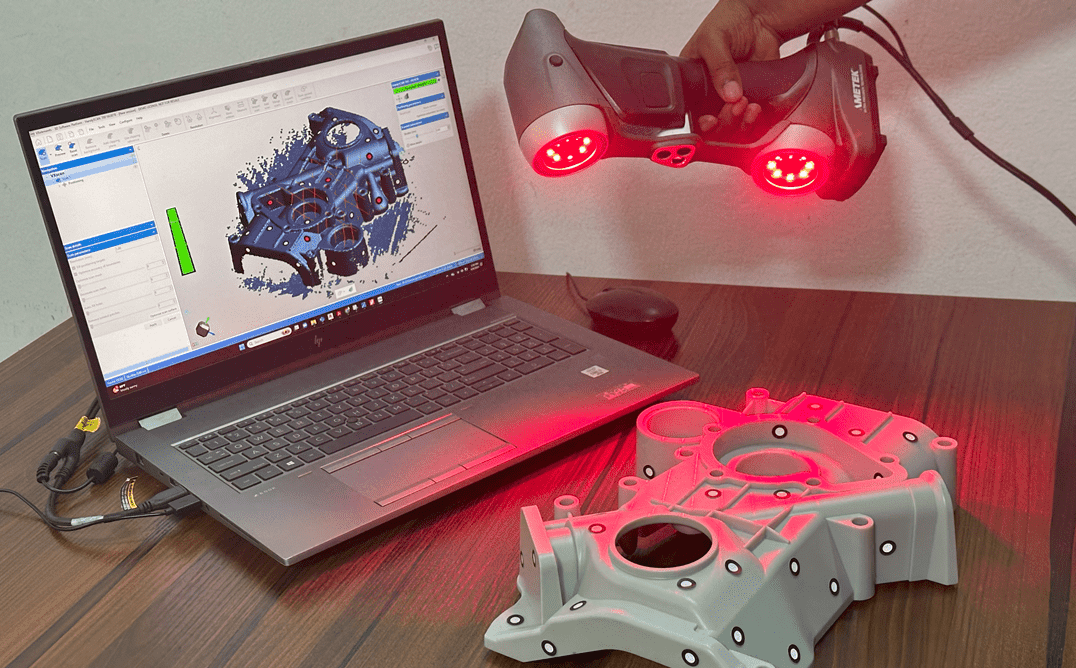

Reverse Engineering

For precision in reverse engineering, trust Creaform as your go-to partner for retrofitting needs

Prototyping

Rapid prototyping is as important as the rest of the product development process.

Industrial Design

We understand how to strike the perfect balance between innovation, aesthetics and functionality

Explore Our Past Work

At Daramyx Solutions Limited, our portfolio speaks for itself. From architectural masterpieces and precision-engineered components to immersive product visualizations, we’ve helped clients across industries turn ideas into reality.

Each project showcases our commitment to:

- Accuracy – Delivering models that meet the highest industry standards.

- Innovation – Using the latest 3D software to bring unique visions to life.

- Functionality – Ensuring every design is ready for manufacturing, simulation, or presentation.

Detailed Designs. Seamless Execution

3D modeling services enhance development with precise visualization and engineering analysis. Skilled drafters create accurate 3D geometries that meet industry standards, delivering highly marketable CAD models for industrial design and prototyping to ensure projects meet objectives with precision and efficiency.

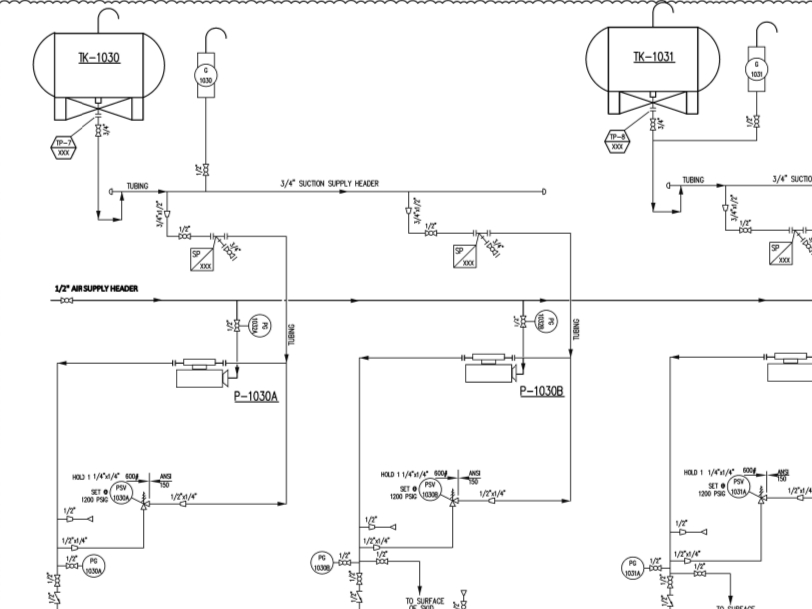

Process Design

Optimizing Efficiency, Reducing Costs, and Enhancing Performance

We provide Process Design services that optimize your workflows, improve efficiency, and enhance safety. Whether you need a new process from the ground up or improvements to an existing system, our engineers develop smart, sustainable solutions tailored to your operational needs.

What Makes Our Process Design Unique?

Data-Driven Approach

We use advanced modeling and simulation to refine processes before implementation.

Regulatory Compliance

Our designs meet international safety, environmental, and industry standards.

Energy Efficiency

We identify opportunities to reduce energy consumption and operational costs.

Scalability & Flexibility

Our solutions are future-proofed for growth and evolving business needs.

Our Process Design Services

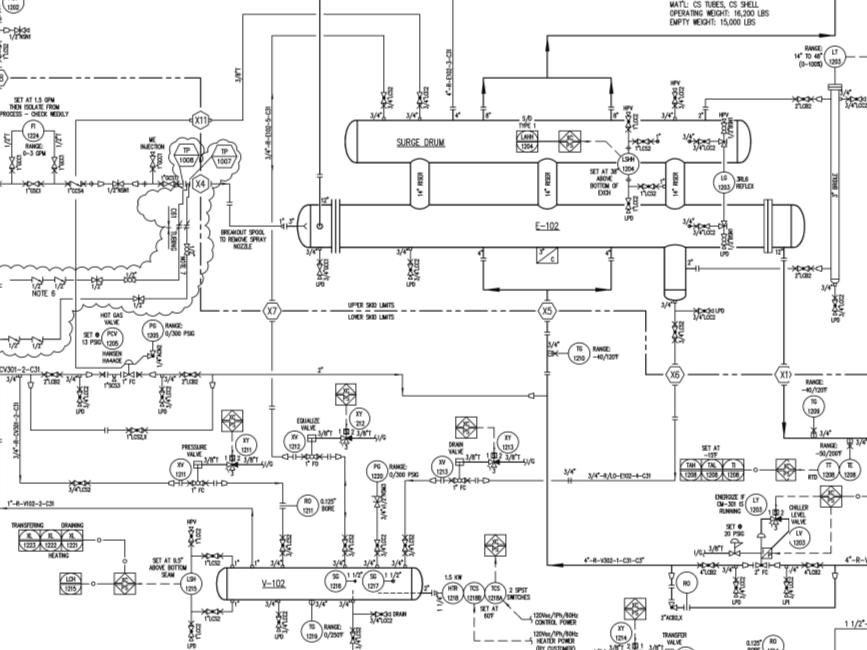

- Process Flow Diagrams (PFDs) & Piping and Instrumentation Diagrams (P&IDs) – Clear schematics of system components and control instrumentation.

- Process Optimization & Automation – Identifying bottlenecks, reducing waste, and integrating automation for peak efficiency.

- Safety & Risk Assessment–HAZOP, FMEA, and risk mitigation strategies to ensure worker and environmental safety.

- Energy & Sustainability Solutions – Incorporating green technologies and energy-saving measures for sustainability.

- Custom Industrial Process Design –Tailored solutions for chemical, mechanical, and manufacturing industries.

Industries We Serve

Oil & Gas

Safe and compliant designs for energy infrastructure.

Industrial Manufacturing

Precision-driven solutions for efficient production.

Energy & Power

Reliable solutions for power generation and distribution.

Food & Beverage

Hygienic and efficient processes for food production.

Partner with Us for Smarter Process Design

Transform your operations with optimized Process Design solutions. Contact us today for a consultation!

Structural Design

Innovative & Resilient Engineering for Stronger Structures

Our Structural Design services ensure the safety, durability, and efficiency of buildings and infrastructure. We apply advance engineering principles to create strong, functional, and cost-effective structural solutions tailored to your project.

Why Choose Our Structural Design Services?

Strength & Durability

Our designs meet load-bearing requirements and environmental challenges.

Advanced 3D Modeling

Visualize your structure before construction with precise simulations.

Code Compliance

We adhere to local and international building regulations and safety codes.

Cost-Effective Solutions

Smart material selection and optimized designs to reduce project costs.

Our Structural Design Services

- Steel, Concrete & Composite Structures – Engineering solutions for various construction materials.

- Load-Bearing & Seismic Analysis – Ensuring structural integrity under stress and environmental forces.

- 3D Structural Modeling & BIM – Advanced visualization for improved accuracy and planning.

- Foundation & Retaining Wall Design – Custom foundations for all types of terrain and applications.

- Structural Health Monitoring – Long-term analysis and maintenance planning for durability.

Industries We Serve

Construction & Real Estate

Reliable structural designs for durable developments

Industrial & Warehousing

Optimized layouts for efficiency and scalability.

Commercial & Residential

Safe, efficient, and modern building solutions.

Transport & Infrastructure

Engineering strong, sustainable transit systems.

Build with Confidence – Let’s Talk!

Whether you’re designing a skyscraper, a bridge, or an industrial facility, our team is ready to deliver innovative Structural Design solutions. Contact us today to discuss your project!

Compressor Aftercooler

Design. Fabrication. Procurement. Performance-Centric Cooling Solutions.

We specialize in the design, fabrication, and procurement of high-performance compressor aftercooler systems tailored for industrial and energy applications. Our aftercoolers are engineered to remove heat and moisture from compressed gases, enhancing system reliability and protecting downstream equipment. Whether deployed as part of a fuel gas treatment skid or integrated into a compressor station, our solutions are built for performance, durability, and operational ease.

Design

Custom Cooling Solutions Engineered to Fit

Our design approach begins with a detailed evaluation of your compression system and performance goals. Every aftercooler is custom-engineered to meet specific outlet temperatures, flow capacities, and gas compositions. We utilize thermal simulation tools and pressure drop analysis to optimize the heat exchange surface and ensure stable, efficient operation. From air-cooled to water-cooled configurations, we offer a full range of design options including shell-and-tube and finned-tube models. Designs are compliant with ASME, PED, or customer-specific standards, ensuring a high level of safety and regulatory adherence.

Accuracy & Detailed

We provide comprehensive drawings, including dimensions, material specifications, welding symbols, and tolerance levels.

3D & 2D Modeling

Our advanced CAD tools help visualize every part before production.

Compliance & Standards

We adhere to international fabrication and welding standards for quality assurance.

Seamless Collaboration:

We work closely with engineers, architects, and fabricators to ensure precision at every step.

Fabrication

Precision-Built for Demanding Environments.

Our aftercoolers are fabricated using high-quality materials and strict quality control standards at ISO-certified facilities. We offer a range of material options such as carbon steel, stainless steel, and corrosion-resistant alloys, depending on the gas composition and operating environment. The fabrication process includes CNC machining, automated welding, and hydrotesting to ensure mechanical integrity. Each unit is pressure-tested, inspected, and can be delivered with optional features such as integrated moisture separators, drain systems, safety valves, and full structural support for skid mounting. This ensures ease of transport and installation in both greenfield and retrofit projects.

Procurement

Integrated Procurement. End-to-End Responsibility.

We manage the full procurement of aftercooler package components from certified heat exchanger cores to valves, instrumentation, and structural assemblies. Our supply chain ensures timely, quality checked delivery, with vendor inspections, logistics, and turnkey packaging including documentation, testing, and international shipping for a site-ready system.

Industries We Serve

Petrochemical

Delivers clean gas to process heaters, reducing fouling and emissions.

Oil & Gas

Removes contaminants from associated or pipeline gas used in upstream and midstream operations.

Energy & Power

Ensures consistent, knock-free fuel supply for turbines and gas engines.

LNG & Floating Facilities

Compact, corrosion-resistant skids built for space-constrained marine environments.

Why Choose Us?

Single-Source Solutions. Guaranteed Results.

By partnering with us, you get technically sound, high-quality compressor aftercooler systems backed by in-house engineering, quality-controlled fabrication, and efficient procurement. Our end-to-end approach reduces coordination and risk, delivering reliable, low maintenance, and efficient systems whether standalone or integrated into larger gas treatment skids tailored to your specifications and industry standards.

Fuel Gas Conditioning

Design. Fabrication. Procurement. Delivered with Precision.

We specialize in the end-to-end delivery of custom-engineered Fuel Gas Conditioner Skids, built to ensure clean, reliable fuel supply for gas turbines, engines, compressors, and other mission-critical systems. From detailed design to turnkey fabrication and streamlined procurement, our skid systems are engineered for performance, mobility, and durability—no matter how demanding the environment.

Design

Engineered to Fit. Optimized to Perform

Our design process begins with a deep understanding of your operating conditions, fuel specifications, and equipment requirements. We use advanced process simulation tools and 3D modeling to create a fully integrated system tailored to your application.

Each Fuel Gas Conditioner Skid is custom-designed to meet precise flow rates, pressure ranges, Methane Number targets, dew point requirements, and LHV specifications. Whether you operate in a standard industrial environment or a hazardous area (ATEX/IECEx), we ensure full compliance with international standards such as ASME, API, and IEC.

Accuracy & Detailed

We provide comprehensive drawings, including dimensions, material specifications, welding symbols, and tolerance levels.

3D & 2D Modeling

Our advanced CAD tools help visualize every part before production.

Compliance & Standards

We adhere to international fabrication and welding standards for quality assurance.

Seamless Collaboration:

We work closely with engineers, architects, and fabricators to ensure precision at every step.

Fabrication

Built for Reliability. Tested for Excellence.

Once the design is finalized and approved, fabrication begins at our ISO-certified manufacturing facilities. We handle everything from pressure vessel construction to system assembly, wiring, and testing—ensuring every component is installed and calibrated to exact specifications.

Skids can be fabricated to accommodate high pressures, sour gas environments, or extreme climate conditions. Offshore and modular variants are also available for FPSO, platform, or remote desert applications.

Procurement

Integrated Procurement. Single-Source Simplicity.

We manage the full procurement lifecycle for your Fuel Gas Conditioner Skid—so you don’t have to. From sourcing specialty valves, pressure vessels, and instrumentation to coordinating sub-vendors and logistics, we streamline the supply chain and assume full accountability for quality, schedule, and cost.

We also offer procurement services as a standalone solution for EPCs and end users managing in-house skid fabrication or installation.

Industries We Serve

Petrochemical

Delivers clean gas to process heaters, reducing fouling and emissions.

Oil & Gas

Removes contaminants from associated or pipeline gas used in upstream and midstream operations.

Energy & Power

Ensures consistent, knock-free fuel supply for turbines and gas engines.

LNG & Floating Facilities

Compact, corrosion-resistant skids built for space-constrained marine environments.

Why Choose Us?

One Partner. Total Responsibility.

Working with us means fewer handoffs, less risk, and better results. We deliver a fuel gas conditioning system that meets your specs, schedule, and budget.

Why choose us:

Custom designs by expert engineers with ISO-certified fabrication with full documentation

End-to-end project management, FAT, SAT, and commissioning support with ongoing technical assistance and spare parts

Our skids provide reliable, mobile, and scalable fuel treatment solutions for plant operators, EPC contractors, and asset owners alike.

Suction Scrubber

Your First Line of Defense Against Contaminants

Suction scrubbers are essential for removing liquids and solids from gas streams before compression. Our Suction Scrubber units are engineered to protect downstream equipment, increase compressor efficiency, and extend equipment life.

Design

Engineered for Clean, Dry Gas

Our suction scrubbers are designed for high-efficiency separation of liquids and solids from gas streams. Each design is tailored based on flow rate, pressure, and expected carryover. Internals such as vane packs, knockout drums, and demisters are selected to maximize separation efficiency. We follow ASME Section VIII and API 12J guidelines, with optional automation, drain systems, and pressure relief devices. Where needed, CFD modeling is used to validate performance and separation efficiency.

Efficient Liquid/Gas Separation

Incorporates advanced internal baffling and demisters for high separation efficiency.

High-Pressure Design

Rated for pressure ranges typical of gas compression systems.

Compliance & Standards

Vessels are designed and fabricated in accordance with ASME Section VIII Division 1.

Skid Integration Available

Can be supplied as a standalone unit or integrated into a complete skid package with piping, valves, and controls.

Procurement

Durable Materials, Proven Suppliers

We procure high-grade vessel materials (SA516, SA106, or specified alternatives) and essential internals like mesh pads, deflectors, and vane extractors. Instrumentation such as level indicators, pressure sensors, and drain valves are sourced from trusted brands. Our robust procurement process ensures all materials meet regulatory standards, with complete documentation and traceability.

Industries We Serve

Petrochemical

Prevents fouling in dehydration and treatment units by removing contaminants early.

Oil & Gas

Separates liquids and solids from wellhead gas to protect compressors.

Energy & Power

Ensures clean, dry gas supply to turbines and engines for stable performance.

LNG & Floating Facilities

Compact, corrosion-resistant skids built for space-constrained marine environments.

Why Choose Us?

Clean Gas. Protected Equipment. Reliable Performance

Partnering with us means reduced risk and reliable results. We deliver custom suction scrubbers built to your specs, schedule, and budget backed by expert design, ISO-certified fabrication, project management, testing, and ongoing support. Our compact, skid-mounted units ensure efficient gas-liquid separation for industrial and energy operations.

Chemical Injection Skid

From Design to Installation – We Build with Precision and Purpose

We offer a comprehensive suite of services to ensure your chemical injection skid is not only engineered for performance but also fully integrated into your facility. Our scope covers the full lifecycle from structural design to installation delivered with precision and quality.

Design

Precision Engineered for Performance

We begin with detailed structural and mechanical design, ensuring the skid frame and support structures meet load requirements, environmental conditions, and space constraints. Our team uses advanced CAD and 3D modeling tools to optimize layout, accessibility, and future maintenance.

Accurate Metering & Control

Precise dosing pumps with integrated automation for reliable chemical injection.

Corrosion-Resistant Materials

Stainless steel and specialty alloys to withstand harsh chemicals.

Safety & Compliance

Safety devices built to IEC/ATEX and ASME standards for secure operation.

Compact & Maintainable Design

Modular skid layout for easy installation and upkeep.

Fabrication

Precision Craftsmanship, Industry Compliant

All fabrication is done in compliance with ISO and relevant industry standards such as ASME and API. We build and assemble skid structures, pipework, and enclosures with high-quality welding, testing, and finishing practices. Every unit is delivered ready for connection and operation.

Civil Works

Solid Foundations, Flawless Execution

ur civil team delivers the complete site preparation—from foundation design and earthworks to formwork, concreting, and surface finishing. We ensure the skid is installed on a stable, level foundation that meets structural and environmental standards.

Procurement & Installation

Accurate Control, Seamless Integration

We manage the full procurement lifecycle for your Fuel Gas Conditioner Skid—so you don’t have to. From sourcing specialty valves, pressure vessels, and instrumentation to coordinating sub-vendors and logistics, we streamline the supply chain and assume full accountability for quality, schedule, and cost.

We also offer procurement services as a standalone solution for EPCs and end users managing in-house skid fabrication or installation.

Industries We Serve

Petrochemical

Supports precise chemical treatment in complex processing environments.

Oil & Gas

For corrosion inhibition, scale control, and hydrate prevention in upstream operations.

Energy & Power

Enhances fuel conditioning and system reliability in turbine and engine applications.

Midstream & Pipeline

Ensures flow assurance and equipment protection during transportation and compression.

Why Choose Us?

Engineered Precision. Reliable Delivery. Trusted Support.

We design and deliver chemical injection skids tailored to your process, built to API, ASME, and IEC/ATEX standards. With full-scope execution—from design and instrumentation to fabrication and civil works—we ensure seamless integration, reliable performance, and long-term support.

35, Total Gospel Road, off Odili Road, Trans Amadi, Port Harcourt, Nigeria.

info@daramyxsolutions.com

+234 902 590 0951

Many Satisfied Clients and Several Completed Projects

We have over the years demonstrated that we are a partner you can rely on for the services that we render

© Copyrights Daramyx Solutions

We are ISO 9001:2015 accredited, demonstrating our commitment to quality management standards.