Laser Rail

Inspection

Ready for our innovations on your next project?

Laser Rail Inspection – Advanced AI-Powered Rail Monitoring

Protecting Lives and Investments with advance Rail Inspection Technology

Railway infrastructure safety is critical, and traditional inspection methods often fall short in detecting early signs of wear and structural issues. Our Laser Rail Inspection system, powered by the Pavemetrics LRAIL™, revolutionizes railway monitoring with AI-driven automated inspection, 2D imaging, and 3D scanning—all in a single pass.

LRAIL™ – The Future of Rail Inspection

Railway safety and efficiency depend on precise, real-time inspections. The LRAIL™ system revolutionizes rail maintenance by combining high-resolution 2D imaging, AI-powered analysis, and 3D scanning into a single, multifunctional solution.

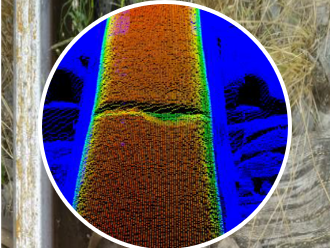

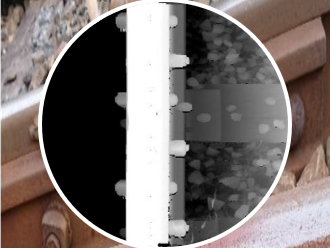

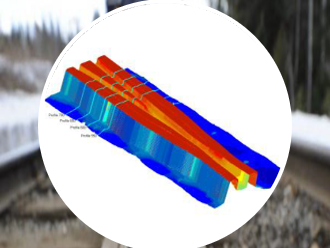

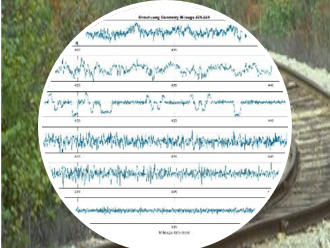

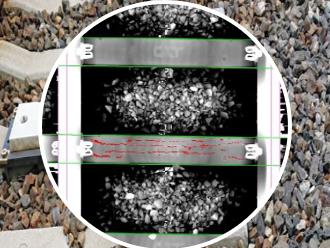

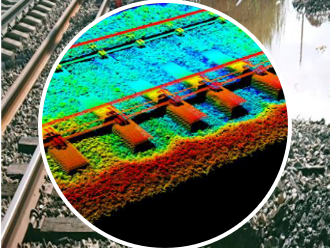

Advanced Imaging & 3D Scanning

- High-Resolution Imaging & 3D Modeling - Captures rail surfaces with 1mm XY and 0.1mm Z resolution for unmatched accuracy.

- Fast & Reliable - Operates 24/7 at speeds up to 120 km/h without disruptions.

- Full Data Integration - Supports JPEG, XML, and 3D models for easy asset management.

AI-Powered Inspection & Real-Time Analysis

- Detects Rail Wear, Defects & Misalignments - Prevents costly failures.

- Automated Tie, Clip & Joint Inspection - Enhances track stability.

- 112 Million Data Points Per Second - Delivers near-real-time processing.

Turnkey & Easy Deployment

- Pre-Calibrated & Ready to Use - Simple installation on high-rail vehicles or flatbed rail cars.

- 800 Miles of Onboard Storage - Extensive data collection with sub-meter GNSS accuracy.

- Wi-Fi Remote Operation - Enables wireless control and data access.

Trusted Worldwide – 500+ Systems Deployed

- Boosts Rail Safety – Early defect detection prevents accidents.

- Maximizes ROI – Reduces inspection costs with AI-driven automation.

- Comprehensive Monitoring – One system, multiple inspection functions.

APPLICATIONS

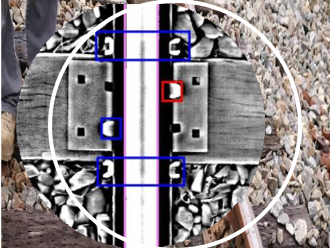

Spike & Anchor Inspection

Ensures secure rail fastening.

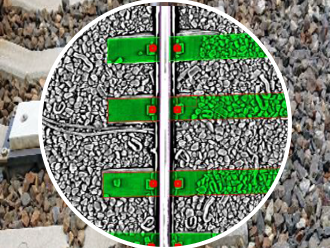

Tie-Plate Inspection

Detects misaligned or damaged tie plates.

Rail Surface Defects

Ensures secure rail fastening.

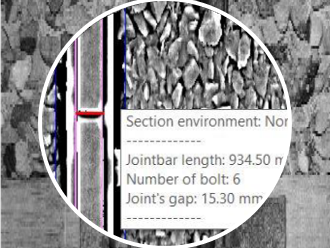

Joint Bar Bolting

Ensures secure rail fastening.

Tie Skew Inspection

Detects misaligned ties affecting track stability.

Crossing Inspection

Assesses rail crossings for wear and defects.

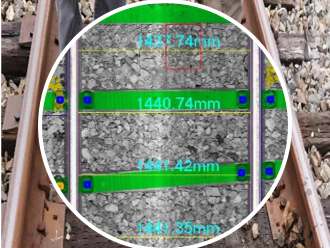

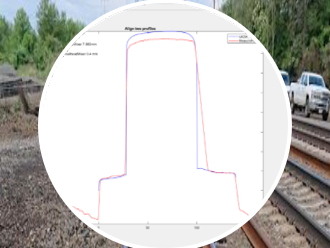

Track Geometry

Measures gauge, cross-level, and alignment accuracy.

Clip Inspection

Identifies loose or missing rail clips.

Rail Wear

Monitors rail degradation to prevent failures.

Joint Gap Inspection

Detects excessive gaps that could lead to misalignment.

Tie Condition

Evaluates tie health for long-term track stability.

Ballast Inspection

Assesses ballast quality for proper track support.

Preventing Accidents Before They Happen

- Railway accidents can be catastrophic, but they are preventable.

- Routine inspections are the key to protecting lives and infrastructure investments.

- Our AI-powered rail inspection technology ensures early defect detection, reducing risks and costly failures.

35, Total Gospel Road, off Odili Road, Trans Amadi, Port Harcourt, Nigeria.

info@daramyxsolutions.com

+234 902 590 0951

Many Satisfied Clients and Several Completed Projects

We have over the years demonstrated that we are a partner you can rely on for the services that we render

© Copyrights Daramyx Solutions

We are ISO 9001:2015 accredited, demonstrating our commitment to quality management standards.