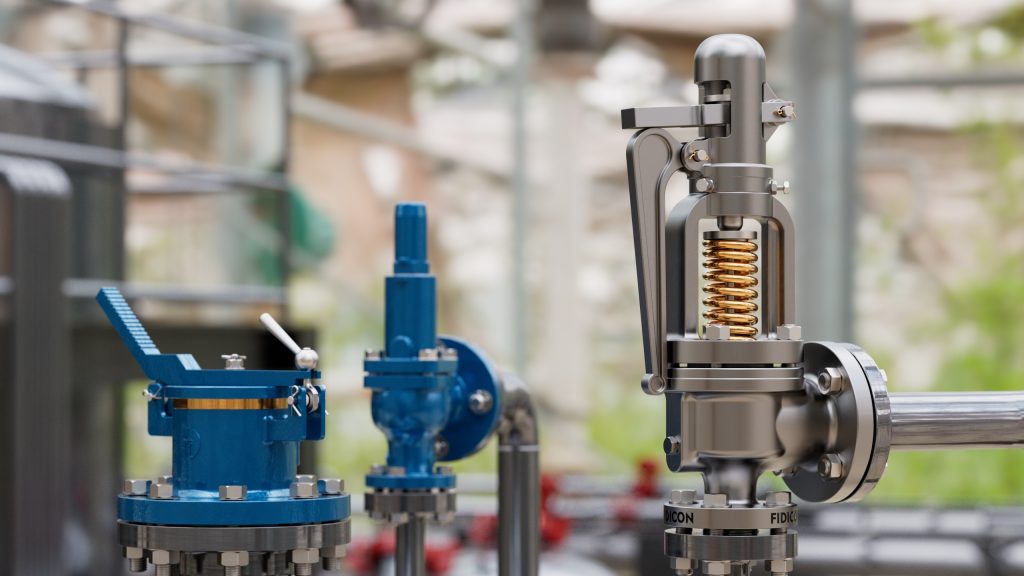

Pressure Relief

Valves

Ready for our innovations on your next project?

Safeguarding Systems, Preventing Overpressure, Ensuring Safety.

PRVs are essential safety devices that protect your systems from overpressure. They automatically release excess pressure when it exceeds a set limit and reseal once conditions return to normal, ensuring safe, reliable, and uninterrupted operation across pipelines, tanks, and industrial equipment.

What is PRV Calibration?

PRV Calibration is the process of testing and adjusting Pressure Relief Valves to ensure they release pressure at the correct set point, maintaining safety and operational efficiency.

Recertification involves inspecting, testing, and validating PRVs after a specified usage period to confirm that they meet industry standards and regulatory requirements.

Importance of Pressure Relief Valve

- Safety Assurance: PRVs are critical safety components designed to prevent equipment overpressure, protecting both assets and personnel from catastrophic failures.

- Operational Efficiency: These devices ensure that pressure levels remain within safe limits, maintaining smooth and uninterrupted plant operations.

Regulatory Compliance: PRVs are mandated by various industrial safety regulations to ensure adherence to global and national safety standards.

Regulatory Mandates for PSV Calibration

We offer comprehensive PRV calibration services to help you maintain compliance with these regulatory standards.

API 527

Seat Tightness of Pressure Relief Valves

API 526

Flanges for Steel Relief Valves

API 576

Inspection of Pressure Relief Valves

ASME PTC 25-2014

Pressure Relief Valve Performance Testing

ASME Sec VIII Div 2

Codes and Laws for Pressure Vessels

ASME XIII

Standards for Boiler and Pressure Vessel Repair

Why Yearly Calibration is Necessary?

- Degradation Over Time: PRVs experience wear and tear due to constant exposure to high pressure, corrosive environments, and operational stress.

- Accident Prevention: Regular calibration guarantees that PRVs respond appropriately during pressure surges, preventing potential explosions, equipment damage, and costly plant shutdowns.

-

Equipment Longevity: Annual calibration ensures that PRVs remain in peak operational condition, extending their service life and reducing maintenance costs.

Which companies need PRVs calibration services?

Oil and Gas

In upstream exploration and downstream refining, pressure relief valves (PRVs) protect equipment from overpressure hazards.

Chemical Processing

Chemical plants handle volatile substances under high pressure, so calibrated PRVs are crucial for safety.

Power Generation

Both conventional and nuclear power plants rely on PRVs to maintain system integrity and prevent overpressure in boilers and reactors.

Manufacturing

Industries such as automotive, electronics, and process plants use PRVs in various equipment to maintain safe operating pressures.

Why Choose Us?

At Daramyx Solutions Ltd, We ensure API & ASME-compliant PRVs calibrations using advanced digital gauges and state-of-the-art equipment for precision and reliability. With a proven track record, we’re trusted by industry leaders to deliver accuracy, efficiency, and safety.

35, Total Gospel Road, off Odili Road, Trans Amadi, Port Harcourt, Nigeria.

info@daramyxsolutions.com

+234 902 590 0951

Many Satisfied Clients and Several Completed Projects

We have over the years demonstrated that we are a partner you can rely on for the services that we render

© Copyrights Daramyx Solutions

We are ISO 9001:2015 accredited, demonstrating our commitment to quality management standards.